| Design Engineering Theory Topics - Home Page |

Fibres and textiles

1 Natural Fibres

- Natural fibres fall into two categories - animal and vegetable.

Animal - Wool

- Made from animal fleece

- Made of protein molecules

- Produce short fibre or staple with a crimp or kink which, with the scales on the fibre, traps air, creating warmth.

- The first step in making wool fabric is shearing it from sheep, then its quality is checked and it is prepared for spinning.

- May be soft or course depending on the sheep breed.

- Examples applications:

- Coats, jumpers, suits, blankets, carpets and upholstery.

- Grey faced Dartmoor wool is suitable for carpet and rug making, while Merino is suitable for fine knitted jumpers.

- ADVANTAGES: Warm, absorbent, breathable, durable, repels rain, hangs well and creases drop out.

- DISADVANTAGES: Dries slowly, susceptible to moth attack, can feel itchy, washes poorly, can shrink and heavy when wet.

- PROPERTIES:

Insulation & Temperature Regulation: The crimped fibres create pockets of air that trap heat, keeping you warm in the cold and helping you stay cool in the heat by reacting to body temperature changes.

Moisture Wicking & Absorption: Wool can absorb a significant amount of moisture vapour from the air and from the skin without feeling wet.

Resilience & Durability: The elastic, coiled structure of wool fibres allows them to spring back into shape, making wool garments resistant to wrinkles and durable over time.

Natural Flame Resistance: Wool fibres naturally resist burning and will smoulder rather than melt or support combustion, making it a safer material.

Odour & Dirt Resistance: The fibre’s natural protective outer layer helps repel dirt, and its ability to absorb and wick moisture inhibits bacterial growth and reduces odour.

Hypoallergenic & Healthy: Wool is a natural protein fibre (keratin) that causes fewer allergies in humans.

Breathability: Wool fibres allow moisture vapor to pass through them and evaporate, keeping the wearer dry and comfortable.

Sustainability: Wool is a 100% natural, renewable, and biodegradable resource.

Vegetable - Plant cotton

- 'Bolls', the fruit cotton plant's fruit are machine-harvested.

- Saw teeth remove waste from the seed pod and the resulting fibre is called lint.

- Cellulose makes the fibre strong, durable and absorbent.

- As the cotton fibres dry they form interlocking flat, twisted, ribbon-like shapes, ideal for spinning.

- Example applications:

- Towels, denim, socks, underwear, T-shirts and bedding

- Short fibres make bandages and insulation

- ADVANTAGES: Cool, absorbent, soft, resists abrasion, withstands frequent washing at high temperature, good drape, durable, does not stain easily, static and cling resistant, available in various weights, can be ironed at high temperatures and good colour retention.

- DISADVANTAGES: Creases easily, burns, shrinks and dries slowly.

- PROPERTIES:

Softness: Cotton fibres are naturally soft, providing a comfortable feel against the skin.

Breathability: Its natural hollow fibre structure allows for good air circulation, which helps regulate body temperature.

Hypoallergenic: Cotton is less likely to cause allergic reactions, making it a good choice for sensitive skin.

High Absorbency: Cotton fibres can hold a significant amount of water or sweat, 24–27 times their own weight.

Wicking: It efficiently wicks moisture away from the body, helping the wearer stay dry.

Slow Drying: While absorbent, cotton also holds onto moisture, causing it to take some time to dry after being wet.

Strength: Cotton fibres have good natural strength.

Stronger When Wet: Wet cotton fibres are significantly stronger than dry ones.

Durability: The fabric is generally durable and resistant to abrasion and wear.

Draping: Cotton has good draping qualities, allowing it to hang well on the body.

Dye Absorbency: It takes dye and prints very well, leading to vibrant colours.

Wrinkles Easily: Cotton is prone to wrinkling and requires ironing.

Shrinkage: It can shrink during the first few washes unless pre-treated by manufacturers.

Resistant to Static: Cotton does not conduct electricity well, so it is resistant to static electricity build-up.

Biodegradable: Being a natural fibre, cotton is biodegradable.

Insulation: Cotton fibres can trap air, providing a layer of insulation that helps retain warmth in cooler temperatures.

2 Synthetic fibres

Synthetic fibers derived from coal, air, water, and petroleum. Synthetic fibres are formed from a chemical reaction between an acid and alcohol.

Examples include: polyester, acrylic, polyamide (nylon), elastane (lycra) and Kevlar.

Polyester

- Polyester is a synthetic fiber derived from coal, air, water, and petroleum. Polyester fibres are formed from a chemical reaction between an acid and alcohol.

- Simple chemical molecules (monomers - a molecule that can be bonded to similar molecules to form long chains) are joined to form polymers by polymerisation.

- The polymer chains are spun into a yarn.

- Example application:

- Raincoats, fleece jackets, children's nightwear, medical textiles and working clothing.

- ADVANTAGES: Strong when wet or dry, dries quickly, resistant to abrasion, soft, hangs well, crease and stain resistant, easy care, can be recycled and resist bacteria.

- DISADVANTAGES: Damaged by acids, low warmth, poor absorbency, does not breathe and not environmentally friendly.

- PROPERTIES:

Strength and Durability: Polyester fibres are very strong, resisting tears, stretching, and abrasion, leading to long-lasting fabrics.

Wrinkle and Crease Resistance: Polyester naturally resists wrinkles and creases, and it maintains its shape well, reducing the need for frequent ironing.

Quick Drying and Moisture Resistance: As a hydrophobic fibre, polyester repels water and doesn't absorb much moisture, causing it to dry quickly.

Shape Retention: Polyester fabrics retain their original shape and are resistant to shrinking and stretching.

Colour Retention: Polyester takes dyes well, resulting in vibrant, long-lasting colours that resist fading over time.

Chemical Resistance: It shows good resistance to most chemicals, making it suitable for industrial applications.

Mold Resistance: Polyester is inherently resistant to mold and mildew, an advantage for outdoor use.

UV Resistance: Polyester fibres are resistant to degradation from ultraviolet (UV) radiation, making them good for outdoor use.

Lightweight: Despite its strength, polyester is a lightweight fibre, making it comfortable for apparel.

Downsides to consider:

Stain Removal: Due to its hydrophobic nature, stains can be harder to remove from polyester fabrics.

Static and Pilling: Polyester can be prone to static and pilling over time.

Non-Biodegradable: Pure polyester is generally not biodegradable.

Acrylic

- Formed by polymerisation of at least 85% acrylonitrile or vinyl cyanide

- The double bond between the first two carbon atoms is broken and the molecules join in a chain.

- Example application:

- Imitation wool knitwear, upholstery fabrics, sportswear, fleece jackets and blankets.

- Acrylic can either be wet or dry spun. They use solvents to dissolve the polymer and then solidify them for their spinning process.

- ADVANTAGES: Warm, dries quickly, good drape, durable, crease resistant and easy care.

- DISADVANTAGES: Poor absorbency, feels stiff and can irritate skin.

- PROPERTIES:

Wool-like Texture: Acrylic is soft and warm with a feel similar to wool, often used as a less expensive alternative or in blends with natural fibres.

Durable and Resilient: The fibres are resilient and resistant to wear and tear, helping garments and fabrics hold their shape well.

Lightweight and Warm: Acrylic is lightweight yet provides good insulation, making it suitable for cold-weather clothing.

Sunlight and Chemical Resistance: It resists fading from sunlight and is resistant to household chemicals and mildew.

Wrinkle and Shrink Resistant: Acrylic fabrics are less likely to wrinkle or shrink, maintaining a neat appearance.

Easy Care: Acrylic is generally easy to wash and care for, often being machine washable and quick-drying.

Breathability: Acrylic is not very breathable and can trap heat and moisture, making it less comfortable for some applications.

Static Electricity: It can generate static electricity, causing clinging.

Flammability: Acrylic is flammable and melts when exposed to high heat.

Pilling: Some acrylic fabrics can pill or fuzz easily, though low-pilling versions are available.

Hydrophobic: Like polyester, acrylic is hydrophobic, meaning it repels water.

3 Woven textiles

- Weaving is the primary way fabric is formed. Woven fabrics are formed by weaving threads over and under each other.

- There are many natural and man-made types of woven fabrics including denim, broadcloth, silk, satin, flannel and twill.

- Fabric thread can be made from cotton, linen, bamboo, polyester and even rayon.

- Weaving turns yarns into a fabric on a loom, which has the arrangement of a warp (vertical) threads held under tension.

- The edges where the weft (horizontal) threads loop back to form a non-fraying edge (selvedge).

Plain weave - Calico

- A simple cotton cloth, the warp and weft pass over and under each other, forming a criss-cross pattern that looks the same on both sides.

- Calico (muslin) is a natural grey colour, which can be either soft or course.

- Applications could be, shirts, bags, bedding and textile crafts.

- ADVANTAGES: It’s strong, hardwearing, hangs well, same on both sides, cheap to make, good background for printing and applied surface designs.

- DISADVANTAGES: It is firm and varies in quality.

- PROPERTIES:

Material & Weave: 100% cotton, plain-woven fabric.

Colour: Natural, unbleached, creamy-grey colour.

Texture: A balance of coarse and soft, though generally described as rough.

Durability: Sturdy and durable due to the strong cotton fibres, though not as robust as denim.

Affordability: A very cheap and cost-effective fabric.

Shrinkage: Prone to shrinkage when washed, so it's best to pre-wash before use.

Biodegradable: As a natural cotton fabric, it is biodegradable and can be easily composted

Twill weave - denim

- The weft yarn goes over 2 or more warp threads, repeated on the row, but steps over one warp thread on the next rows to make a diagonal pattern.

- Denim is blue in the warp and white in the weft.

- Applications could be, jeans, jackets, curtains, blankets and soft furnishings.

- ADVANTAGES: Hard wearing, strong, hangs well, less stiff and more interesting to look at than plain weave.

- DISADVANTAGES: Frays, thickness makes it hard to use.

- PROPERTIES:

Strength & Durability: Denim is robust and long-lasting, capable of withstanding frequent use and heavy wear without easily tearing or snagging.

Twill Weave: Its defining feature is the twill weave, where white weft threads are woven under two or more coloured warp threads, creating the signature diagonal lines on the fabric's surface.

Softness & Comfort: While often initially stiff, denim softens over time with wear and washing, offering a comfortable feel.

Breathability: Made primarily from cotton, denim is a natural and breathable fabric that allows air to circulate.

Moisture-Wicking: The cotton fibres in denim have natural moisture-wicking properties.

Versatility: Denim is used for a vast range of products, from jeans and jackets to other apparel and even upholstery.

Indigo Dyeing: Warp threads are dyed with indigo, which fades over time, giving denim its iconic look and ability to develop unique patterns with wear.

Weight Variation: Denim comes in various weights, with heavier options for rugged garments and lighter versions for warmer weather.

Stretch Ability: While traditional denim is rigid, modern versions can include elastane (spandex) to provide stretch and flexibility for a more comfortable fit.

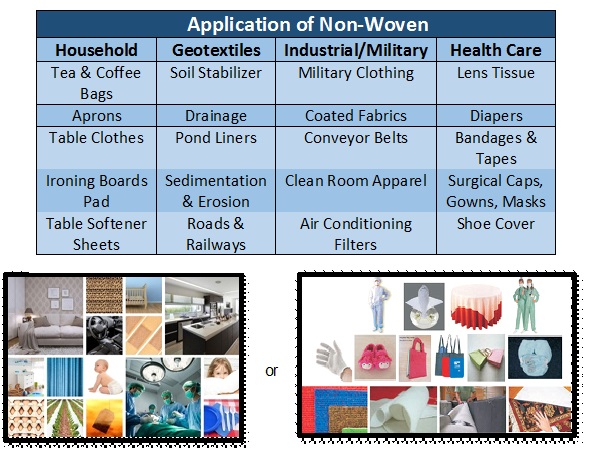

4 Non woven textiles

- Because it is a kind of form that does not require spinning weaving fabric, but the textile fiber or filament for directional or random support, the formation of the fibre network structure, and then the mechanical, thermal or chemical methods and strengthening into.

- Nonwovens break through the traditional textile principle, and have the characteristics of short process flow, fast production, high yield, low cost, wide use and many sources of raw materials.

- Fibres are layered at different angles to form a web, joined by either felting or bonding.

- Bonding joins the fibres with heat, solvents or adhesives, so is cheap to produce but not as strong as woven or knitted fabrics.

Felted wool fabric

- Scaly fibres of wool or hair become tangled as they are rubbed together when wet.

- Heat and pressure are applied to join them,

- Applications could be, pool table surfaces, hats, coats, slippers, applique quilts and wall hangings.

- ADVANTAGES: Resists chemicals and fire, does not unravel or fray, can be repeatedly compressed and released without deforming, excellent sound insulator and environmentally friendly.

- DISADVANTAGES: Expensive, no drape, not stretchy and deforms when wet.

- PROPERTIES:

Thermal & Acoustic Insulation: Felt traps heat and dampens sound due to the air pockets within its dense, matted fibres.

Durability & Resilience: Its tangled fibre structure makes felt highly resistant to tearing and wear, retaining its shape and strength over time.

Non-Fraying Edges: Unlike woven fabrics, felt does not ravel or fray, allowing for clean, raw edges when cut.

Flame Retardant: Wool felt is naturally resistant to fire and self-extinguishing.

Moisture Wicking & Breathable: Wool's natural fibres can absorb moisture vapor and release it, preventing it from feeling damp and maintaining insulating properties.

Moldability: Its non-woven, dense texture makes felt easy to mold, cut and shape for various applications.

Hypoallergenic: Pure wool felt is non-toxic, non-allergic, and doesn't irritate sensitive skin.

Natural & Biodegradable: Made from animal fibres, wool felt is a natural, sustainable, and environmentally friendly resource.

Chemical Resistance: Wool felt shows good resistance to various chemicals.

Versatility: It can be made into a variety of thicknesses, from soft enough for sewing to hard enough for industrial uses.

Shrinkage: Wool felt can shrink when washed.

Fuzziness: Felt can become fuzzy over time but does not fray.

Bonded fibres/webs

- Does not fray, weaker when wet, can be produced in a range of weights and not very strong.

- Applications could be, fusible interfacing, wet wipes and disposable overalls.

- ADVANTAGES: Does not fray, cheap to produce, stable and so retains its shape.

- DISADVANTAGES: Not very strong, does not drape and sometimes weaker when wet.

- PROPERTIES:

Enhanced Strength and Stability: Bonding can increase the stability and strength of the resulting fabric, as two different materials are held firmly together.

Durability: The combined structure and resistance to wear and tear can make bonded fabrics exceptionally durable, leading to longer lifespans.

Water Resistance and Insulation: Bonding can incorporate membranes or foams, creating fabrics with improved water resistance and insulating qualities.

Non-Fraying: Unlike traditional woven or knitted fabrics, bonded fabrics do not fray because there are no yarns to unravel.

Versatility and Customization: The bonding process allows for the combination of various materials (textiles, foams, films), enabling the creation of fabrics with tailored properties for specific needs.

Stability and Shape Retention: They are stable to washing and dry-cleaning, and they are able to hold their shape, making them useful for garments and upholstery.

Potential Weakness: Some types of bonded fabrics, especially those made from webs of individual fibres, can be weaker and more prone to tearing compared to strong, traditional woven fabrics.

5 Knitted textiles

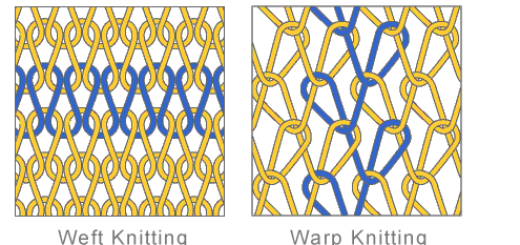

Weft knitted

- Weft knitting is the most common type of knitting, it is the process of making a fabric by forming a series of connected loops in a horizontal or filling-wise direction.

- It can be produced on both flat and circular knitting machines or by hand.

Uses:

- Tailored garments, like jackets, suits, or sheath dresses are made from weft knitting.

- Interlock knit stitch is wonderful for making T-shirts, turtlenecks, casual skirts, dresses and children's wear.

- Seamless hosiery, knitted in tubular form, is produced by circular knitting machines.

- Circular knitting is also used for the production of fabrics used in sports having high stretch ability and also dimensional stability.

- Knitted hats and scarves are used in the winter season are made through weft knitting.

- Industrially, metal wire is also knitted into a metal fabric for a wide range of uses including the filter material in cafeterias, catalytic converters for cars and many other uses.

Advantages

- Stretchy, comfortable, fast production

Disadvantages

- Ladders easily

PROPERTIES:

High Extensibility and Elasticity: Weft knits possess high stretch, particularly in the width (course-wise) direction, providing flexibility and comfort that allows them to move with the body.

Soft Handle and Comfort: The soft, smooth texture created by the loops contributes to a comfortable and pleasant feel against the skin.

Flowing Drape: The loop structure gives weft knits a fluid drape, which is excellent for garments like dresses and skirts that require graceful movement.

Breathability: Weft knits allow for good air circulation due to the open spaces between the yarn loops, contributing to their breathability.

Wrinkle Resistance: The inherent stretch and recovery of knit fabrics make them naturally wrinkle-resistant.

Runnability and Unravelling: A significant drawback is their tendency to snag, run and completely unravel if a yarn breaks, making them less durable than woven fabrics.

Curling Edges: Many weft knits, especially single jersey, will curl at the edges, requiring specific handling or techniques to prevent.

Warp knitted

- Warp knitting is the process of making a fabric with a machine by forming the loops in a vertical or warp-wise direction; the yarn is prepared as warp on beams with one or more yarns for each needle.

- The fabric has a flatter, closer, less elastic knit than weft knit and is very often run resistant.

Uses:

- Tricot knit a type of warp knitting is used in the making of light weight fabrics usually inner wear like panties, brassieres, camisoles, girdles, sleepwear, hook & eye tape, etc.

- In apparel warp knitting is used for making sportswear lining, track suits, leisure wear and safety reflective vests.

- In household warp knitting is used for making mattress stitch-in fabrics, furnishing, laundry bags, mosquito nets and aquarium fish nets.

- The inner linings and inner sole linings of sports and industrial safety shoes are made from warp knitting.

- Car cushion, head rest lining, sun shades and lining for motorbike helmets are being made from warp knitting.

- For industrial uses PVC/PU backing, production masks, caps and gloves (for the electronic industry) are also made from warp knitting.

- Fabrics for printing and advertising are also produced from warp knitting.

- The warp knitting process is also being used for the production of bio-textiles. For example, a warp knitted polyester cardiac support device has been created to attempt to limit the growth of diseased heart by being installed tightly around the heart.

Advantages

- Fairly stretchy, retains heat, does not unravel

Disadvantages

- Can lose shape, curls at edges

PROPERTIES:

Dimensional Stability: This is a hallmark of warp knits, meaning they maintain their original shape and size even when stretched or washed.

Run Resistance: Unlike weft knits, warp knits are less prone to unravelling or spreading if a yarn breaks, making them more durable for heavy-duty applications.

Controlled Stretch: Warp knits have a specific and measurable amount of stretch, which is crucial for applications like compression garments, shapewear, and medical devices.

Smooth & Consistent Surface: The construction results in a flat, smooth and uniform surface, ideal for high-quality designs, prints and consistent textures.

Breathability: Many warp-knitted fabrics are breathable, especially when designed with mesh structures, allowing for good airflow and moisture management.

Versatility in Structure: Warp knitting can create a wide range of structures, including plain, mesh, spacer, and 3D fabrics, accommodating diverse design and functional needs.

Durability: The tight, interlocking loop structure enhances abrasion resistance and reduces snagging and pilling, contributing to the fabric's longevity.

6 Properties of textiles

Elasticity - amount of stretch

- tested by gradually increasing the force on the fibres until breaking point

- At low lods the fibres obey Hooke's law - stretch is proportional to the load and the fibres will return to their original shape.

- Clothes made from fibres that recover will maintain their shapes and not keep creases.

Resilience - resistance to being deformed or compressed

- Fibres should spring back vigourously when pressure has been applied.

Loft (compressional resiliency) is the ability to return to original thickness after being compressed or squashed, or to resist creasing.

Durability

- Weave: Fabrics with well-balanced patterns and yarns wear out more evenly.

- Fibre: Natural materials like cotton, canvas, and leather are durable.

- Tensile strength: Some fibers with high tensile strength include aramid, nylon, polypropylene, and polyester.

7 Recap

- Natural fibres come from plants and animals

- Synthetic fibres are artifically made from chemicals

- The two main types of weave are plain and twill

- Non woven fabrics are made by either felting or bonding

- Knitted fabrics are either warp or weft knitted.

Exam style questions

- Explain one benefit of using wool felt for constructing a hat

- Explain one disadvantages of using wool felt in a hat.

- Describe the advantages and disadvantages of cotton.

- Explain how felt is made.

- Devise a test for the resilience of different textiles

- Explain why a test for elasticity would be important when choosing fabrics for swimwear.