| Design Engineering Theory Topics - Home Page |

Papers and Boards

1 Key terms

Paper

- A thin flat material made from natural fibres weighing less than 220 gsm.

Board

- Board is thicker than paper or layers of paper more than 220gsm.

2 Paper

- Paper is a thin material produced by pressing together moist fibres of cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets. It is a versatile material with many uses, including writing, printing, packaging, cleaning, and a number of industrial and construction processes.

- In Europe, paper and board is measured in grams per square metre (gsm).

- This means the number of grams a 1m X 1m sheet weighs 80-220gsm.

- There is a suggestion that the thicker the paper, the better the quality.

- Standard copier paper is usualy 80gsm. with typical writing paper being 120gsm.

Copier Paper

- Weight - 80gsm.

- Description - Thin, lightweight, cheap, bright white paper, with a smooth, bleached, uncoated surface.

- Uses - Writing, printing and drawing.

- Advantages - Takes colour well, good surface for pencils, pens and markers, cheap, readily available and in a range of colours.

- Disadvantages - Can be prone to jamming printer feed mechanisims.

Cartridge Paper

- Weight - 120-150gsm.

- Description - Creamy, thick heavyweight paper.

- Uses - General drawing and printing, can be used with watercolour paints without buckling.

- Advantages - Accepts most drawing media, opaque.

- Disadvantages - Costs more than copier paper.

Tracing Paper

- Weight - 60-90gsm.

- Description - Thin, smooth and translucent, made by beating to remove air and processing to make a dense, strong paper.

- Uses - Art, making copies, envelop windows and overlays on working drawings.

- Advantages - Strong, translucent.

- Disadvantages - Can be expensive, limited ink absorption and longer drying time.

3 Boards

- Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper.

- According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions.

- Paperboard can be single- or multi-ply. Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging.

- Another end-use would be graphic printing, such as book and magazine covers or postcards. Sometimes it is referred to as cardboard, which is a generic, lay term used to refer to any heavy paper pulp–based board.

- Paperboard is also used in fine arts for creating sculptures.

Folding boxboard

- Description - Stiff layers consisting of:

- A printable bleached virgin pulp top surface.

- Unbleached yellowish centre layers.

- A bleached inside layer.

- Uses - Cereal boxes, food and health packaging and cartons.

- Advantages -

- Excellent for scoring and bending without splitting.

- Accepts print well.

- Inexpensive.

- Disadvantages -

- Lower strength than solid white board.

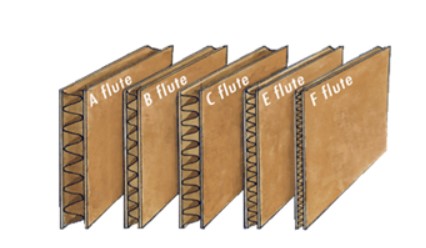

Corrugted board

- Description -

- Two or more layers of fluted paper sandwiched between to paper liners.

- Available in different thicknesses.

- Strong and lightweight.

- Uses - Protective packaging, for example boxes for electrical products and CD sleeves.

- Advantages - Impact resistant, inexpensive, recyclable.

- Disadvantages -

- Brown finish does not convey quality.

- Can deform under pressure.

- Not water resistant.

Solid White Board

- Description -

- Strong, rigid board made from pure, bleached wood pulp.

- Excellent printing surface.

- Uses - Book covers, food, cosmetics and medicine packaging.

- Advantages - Strong, rigid and accepts print well.

- Disadvantages - Can be expensive.

4 Properties

Flexibility

- Amount of material bends when a force is applied (stiffness), determined by its thickness and weight.

- Flexural stiffness is resistance to an external bending force.

- Handling stiffness is the ability to support its own weight.

Printability

- Ability to accept a printed image onto its surface (porosity).

- Affected by surface properties, such as smoothness or finish, and structural properties, such as bulk or thickness.

- Not the same as print quality, which is determined by other factors such as alignment of plates on the machinery.

Biodegradability

- Ability to be broken down by bacteria or other biological means.

- Most uncoated paper products are biodegradable because they are made from wood pulp.

- Compostable means that a material can biodegrade in less than 12 weeks.

5 Sample questions

- Paper and card are extremely useful materials that are processed from wood fibres. They come in many different sizes and forms.

- How many paper products have you used today?

- Why do you think that some boards are laminated with other materials, such as foil.

- How many different paper sizes do you know (list 3).

- The box in the image above is used to package CDs sent to a supermarket.

- Explain one reason why this material is suitable for the box. (2)

- Explain one disadvantage of this material. (2)

- Name three different paper types.

- State an advantage of using folding boxboard.

- Explain why printing might affect the quality of a finished product?

- Describe and compare the properties of two different boards. Evaluate which one would be best for a new perfume package?